Videojet 7920

Videojet 7920

UV laser marking system

Enhance your code quality and streamline automation with powerful Videojet SmartFocus™ technology on the 7920 UV laser. Secure long-lasting reliability with the exclusive five-year Videojet SourceSecure™ warranty.

![]() 2D code ready

2D code ready

Contact Us

Videojet 7920

Videojet 7920

UV laser marking system

Enhance your code quality and streamline automation with powerful Videojet SmartFocus™ technology on the 7920 UV laser. Secure long-lasting reliability with the exclusive five-year Videojet SourceSecure™ warranty.

![]() 2D code ready

2D code ready

Contact Us

Why the Videojet 7920 stands out

Product advantages

- Eliminate manual focus adjustments and improve marking quality across product sizes and substrates by relying on Videojet SmartFocus™ technology to auto-adjust the focal distance

- Leverage the five-year Videojet SourceSecure™ warranty to safeguard your laser source, providing five years of source protection

- Maintain exceptional print quality with uniform spot-size marking across the entire field with no code degradation at the edge, even on curved surfaces

- Maximize line efficiency with flexible integration into any setup, including tight areas and existing machines, thanks to the compact design and flexible beam turning units

- Seamlessly integrate into your line and boost productivity with enhanced connectivity options

Have questions about the Videojet 7920 or UV laser technology?

Our coding experts are ready to assist!

Contact Us:

Applications in focus

Inclusive testing options for quality confidence

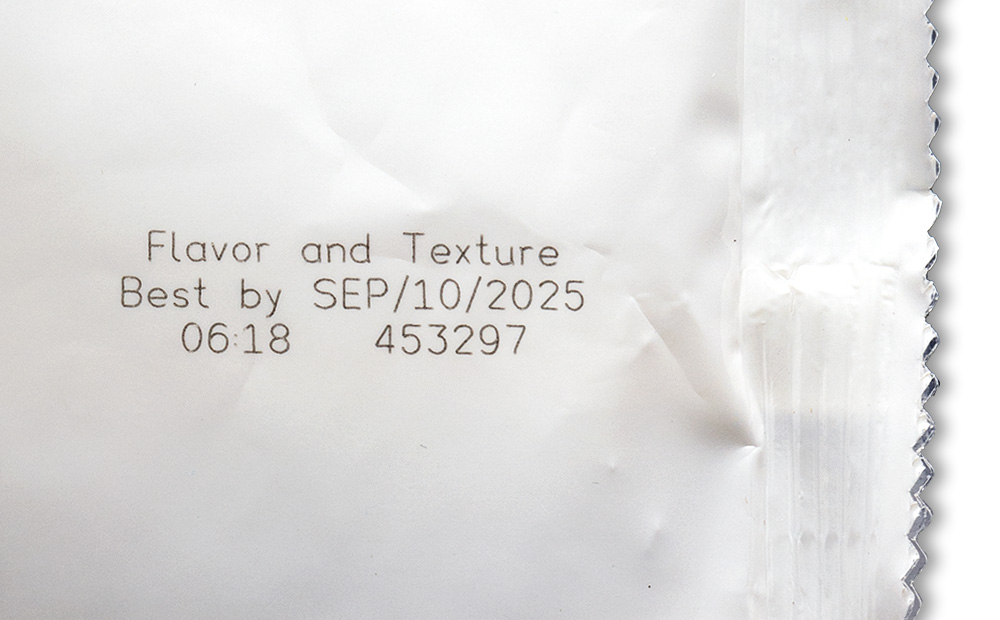

Videojet sample testing ensures your product codes meet specification. You’ll receive a detailed report with optimized setup parameters for your specific code and substrate. Oxygen and water permeations tests are available to validate that the packaging integrity remains intact after UV laser marking.

Contact

Trusted by industry leaders

Meet the experts

- Sajin Unnikrishnan

- Hanno Schmidt

- Bruno Aquilino

- Gary Hunt

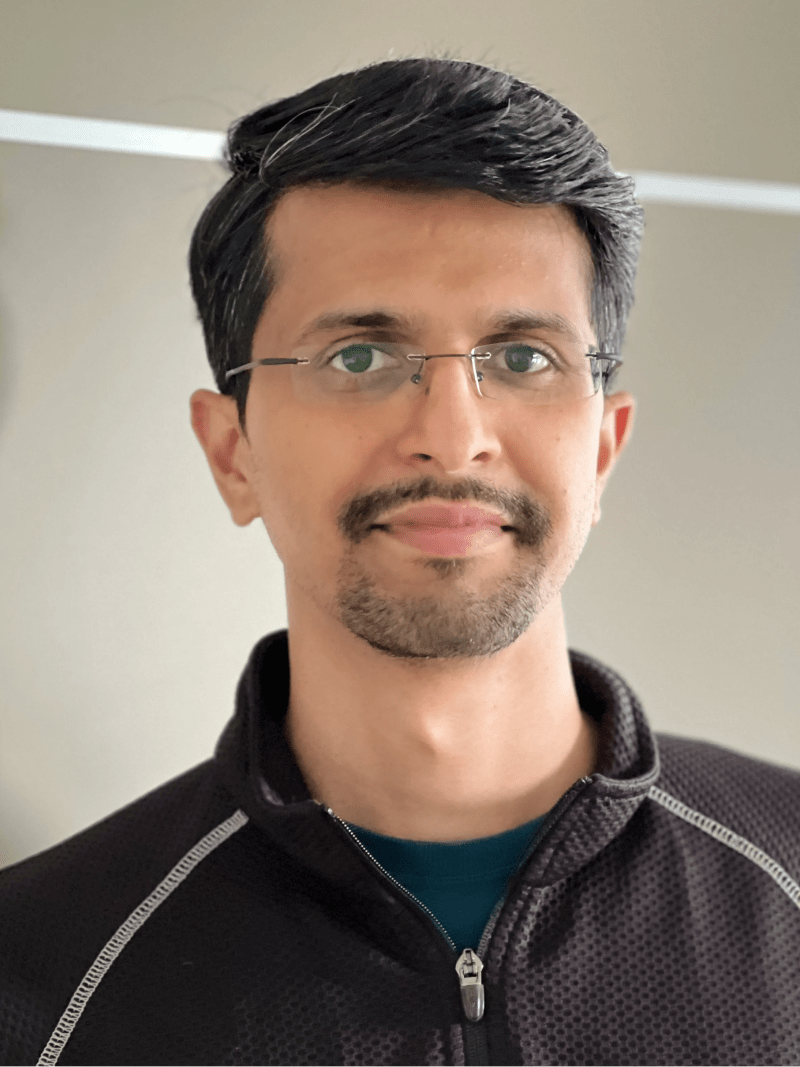

Sajin Unnikrishnan

“Our laser markers are built to last, ensuring reliable performance, easy maintenance, and comprehensive spare part support. This means you can trust your system to keep running smoothly for years to come.”

With 16 years of experience as a Senior Mechanical Design Engineer, Sajin has been actively involved in numerous projects from start to finish. Holding a Bachelor’s degree in Engineering and an MBA, he joined Videojet in 2015. Since then, he has been instrumental in developing innovative solutions for Videojet’s laser and CIJ technologies, playing a key role in driving the company’s growth and success.

Hanno Schmidt

“I am impressed by the exceptional blend of precision and speed in our laser marking systems, which provides unparalleled reliability to our customers, allowing them to concentrate on the essential tasks in their daily operations.”

With a background in mechanical engineering and prior experience as a design engineer, Hanno joined Videojet in 2019 as a Project Manager. They began by overseeing the launch of a key laser product, responsible for its production introduction. Their subsequent roles have included leading the development of a fiber laser solution for canning applications and managing the rollout of innovative laser head technology. Throughout Hanno’s tenure at Videojet, they have successfully led projects across all major laser categories: UV, fiber, and CO2.

Bruno Aquilino

“Working with laser technology embodies the union between future aspirations and cutting-edge innovation. Providing the best solution for our customers, focusing on productivity and sustainability, is what continually drives our processes and customer solutions.”

Bruno Aquilino is Global Laser Product Manager at Videojet, based in São Paulo, Brazil. With 18 years of experience and a background in Electrical Engineering and Marketing, he brings a unique blend of technical expertise and customer insight. Since rejoining Videojet in 2019, Bruno has played a key role in aligning product innovation with real customer needs — drawing from his earlier experience in technical support, laser sales, and regional management across LATAM. His deep understanding of both CIJ and laser technologies helps drive smarter, more sustainable solutions across global markets.

Gary Hunt

“I’m responsible for the vision and strategy of all digital solutions across Videojet. Understanding our customers needs and challenges today and tomorrow, and providing easy to use digital solutions to solve those needs.”

Gary is Senior Director of Digital Product Management at Videojet, leading the vision and strategy for all digital solutions across the company. With 15 years of industry experience, he works closely with customers to understand their current and future needs, delivering intuitive digital tools that help them improve efficiency, enhance traceability, and achieve long-term success.

Find out more

Select a category:

- Brochure & specs

- FAQs

- Learn about laser

The Videojet 7920 UV laser offers cutting-edge features designed for superior performance and reliability:

1. Videojet SmartFocus™ technology ensures optimal code quality on various substrates without manual adjustments.

2. The Videojet SourceSecure™ warranty provides five years of laser source protection for long-term reliability.

3. The 7920’s compact design and flexible beam turning units allow seamless integration into tight production lines.

4. Enhanced connectivity options boost productivity by integrating smoothly with existing systems.

5. Videojet 7920 UV laser supports high-speed marking, making it ideal for industries requiring precise and efficient coding.

UV laser marking systems, like the Videojet 7920, use ultraviolet light to create photochemical reactions that result in crisp, high-contrast marks on sensitive materials like glass, film, and mono-materials packaging. Ideal for applications requiring fine detail without damage to the material.

CO₂ laser marking systems utilize a gas laser with CO₂ as the medium to engrave non-metal materials, offering high-speed marking for various plastics, cardboard/paperboard, glass, wood, and foil with precise and clean 2D codes, alphanumeric text, logos, and more.

Fiber laser marking systems employ a solid-state laser that’s highly effective on metals and engineered plastics, providing high-contrast, permanent codes, text and more with excellent durability and resistance to wear. Ideal for high-density plastic, stainless steel and other metals, and glass.

UV laser marking is a game-changer across multiple industries:

1. Electronics manufacturers benefit from its precision in marking lightweight and thin materials.

2. The medical and healthcare sector uses UV lasers for marking medical devices with micron-level accuracy.

3. Automotive manufacturers rely on UV lasers for marking parts and components without damaging surfaces.

4. In the packaging and printing industry, UV lasers help ensure high-quality, durable marks on various materials like plastic films and foils.

5. Additionally, semiconductor and renewable energy industries leverage UV laser technology for precise processing and identification.

Absolutely! The Videojet 7920 UV laser is designed to reliably mark on flexible packaging, including plastic film and mono-materials used in CPG applications. Its Videojet SmartFocus™ technology helps ensure optimal code quality on various substrates, including flexible materials, without manual adjustments, while minimizing the chance of damaging the material barrier. The laser’s compact design and flexible beam turning units allow seamless integration into tight production lines.

Yes! The Videojet 7920 UV laser is designed for automated production lines. Its compact design and flexible beam turning units facilitate easy installation even in tight spaces. Enhanced connectivity options help to smooth integration with existing systems, boosting productivity. Videojet SmartFocus™ technology helps ensure optimal code quality on various substrates without manual adjustments, reducing or removing the requirement for adjustable mechanical mounting.

Videojet SmartFocus™ technology in the Videojet 7920 UV laser significantly enhances performance by automatically adjusting the focal distance for optimal code quality on various substrates. This feature eliminates the need for manual adjustments after job setup, and helps to reduce downtime and provide consistent, high-quality marking. Videojet SmartFocus™ technology also supports high-speed marking, enabling efficient processing and increased throughput. Its ability to maintain precise focus on moving and stationary products makes it ideal for diverse production environments.

When integrating a UV laser into a production machine and in order to achieve a Class 1 laser system, several safety precautions are essential:

1. Ensure the laser is enclosed in a light-tight housing to prevent any harmful radiation exposure.

2. Use interlocked access panels that disable the laser when opened.

3. Install proper ventilation systems to manage fumes generated during marking.

4. Regularly inspect and maintain the laser equipment to ensure safe operation.

5. These measures collectively ensure a safe and compliant Class 1 laser system.

The marks produced by the Videojet 7920 UV laser are exceptionally durable. They are designed to withstand harsh environmental conditions, including exposure to water, chemicals, and extreme temperatures. The high-contrast, high-quality marks remain clear and legible over time for long-lasting identification and traceability. This durability makes the 7920 UV laser ideal for industries where products are subject to rigorous handling and challenging conditions.

Explore additional options

When it comes to marking and labeling your products with the utmost care and precision, there are several alternatives to the Videojet 7920 UV laser marking system that merit consideration. Each alternative offers unique advantages tailored to different needs and applications.

Contact us

Laser marking system

Videojet 3350 CO₂ Laser

Laser marking system

Videojet 7510 Fiber Laser

Continuous Inkjet (CIJ)

Videojet 1880 UHS

Contact Us

Let Us Find the Right Solution for Your Business

A Coding Expert will contact you within 1 business day

Contact us Today for Free Consultation & Demo Samples:

South East Asia, Australia & New Zealand:![]() : +65-8228-8416

: +65-8228-8416![]() : Marketing.Singapore@videojet.com

: Marketing.Singapore@videojet.com

Videojet Thailand![]() : +66 92 272 0132

: +66 92 272 0132

Videojet Vietnam![]() : +84 83 805 1033

: +84 83 805 1033

Videojet Presence in SEA/ANZ Countries