Thermal Transfer Overprinters (TTO)

Full line of thermal transfer overprinters for printing variable content on flexible packaging and labels

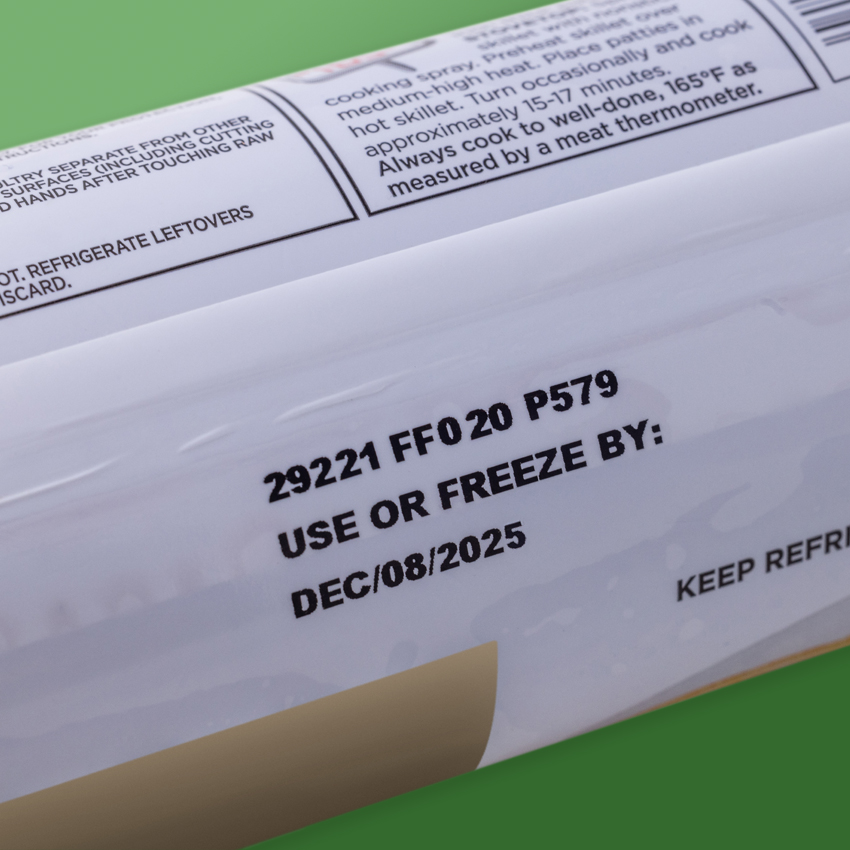

Whether marking simple date and time codes, complex regulatory codes, ingredient lists, or marketing information, Videojet TTO printers help keep your production lines running at peak performance. Print high-resolution images on flexible packaging, film, and labels while minimizing the downtime and costs associated with production changeovers.

Videojet TTO printers

Thermal transfer overprinter (TTO)

Videojet DataFlex 6530 & 6330

Thermal transfer overprinter (TTO)

Videojet DataFlex 6230

Applications

Thermal transfer overprinters are used for high-speed printing on flexible packaging, labels, and tags. They provide durable, high-quality printing of batch codes, expiration dates, barcodes, and logos, making them ideal for the food, pharmaceuticals, and consumer goods industries. TTO’s ability to print on various substrates enhances versatility in packaging operations.

FAQs

A thermal transfer overprinter is a printing device that uses heat to transfer ink from a ribbon onto packaging materials, such as flexible films. The process involves a thermal print head that applies heat to the ribbon and then melts the ink and transfers it onto the substrate. TTOs are commonly used for high-speed printing of variable information like barcodes, expiration dates, and lot numbers on flexible packaging.