FAQs: Which is right for you—preprinted or in-line printed 2D codes?

Carl Chaplin

Videojet Regional Product Manager

Preprinted 2D codes, In-line printed 2D codes, GS1 Sunrise, Traceability and compliance, Code assurance software

Preprinted 2D codes are best suited for static information, such as consistent GTINs and fixed serial numbers, while in-line 2D codes offer the flexibility to include variable data like batch numbers, expiration dates, and dynamic elements. Choosing the right solution depends on your traceability goals, production workflows, and compliance requirements.

What’s the main difference between preprinted and in-line printed 2D codes?

Preprinted codes are static and applied to packaging materials before they reach the production line, usually by the packaging converter. In-line printed codes, on the other hand, are generated during production and can include variable data such as batch numbers, expiration dates, or serialization.

This distinction is key to making decisions about flexibility in your coding operations. It’s also a consideration when planning production line changes for the implementation of GS1 Sunrise 2027.

What are the benefits of using preprinted 2D codes?

Preprinting is a great option when the data in your codes remains consistent across all product packaging—such as GTINs (Global Trade Item Numbers) or fixed serial numbers. A single string of data is used across the entire set of materials, and only a single design is needed.

If your packaging supplier uses digital or hybrid presses, they may also support sequential code printing, allowing you to incorporate unique codes without altering your existing production process.

When should manufacturers choose in-line 2D code printing over preprinted codes?

Manufacturers should choose in-line 2D code printing when there is a need to encode live production data, such as date and lot codes, and/or serialization. While GS1 Sunrise 2027 does not require variable 2D codes, adopting them can provide added benefits for your operations.

In-line printed 2D codes enable brands to:

- Enhance traceability throughout the value chain

- Respond quickly to recalls

- Prepare for future regulatory and retailer requirements

Additionally, in-line printing supports dynamic features such as product authentication, inventory management, and customized messaging. These capabilities align with the broader objectives of Sunrise 2027.

What changes do manufacturers face when switching to in-line 2D code marking?

Changing to in-line printing brings added flexibility and control to your production process. It allows you to generate and apply variable data, such as batch numbers and expiration dates, directly on the packaging line.

While this approach supports lean manufacturing by reducing scrap materials with outdated codes and other printed information, it also shifts the responsibility for code quality to your production team. Late-stage customization becomes possible, enabling manufacturers to adapt to evolving business and regulatory needs.

What are the key steps to successfully print 2D codes in-line?

To help ensure a smooth transition to in-line printing, consider the following steps now:

- Understand what information you want within your 2D code.

- Train your team on GS1 standards, data collection processes, and code verification methods.

- Work with your coding equipment provider to decide which technology would be best for your 2D code printing applications.

- Implement centralized print job management tools, such as Videojet CLARiSUITE®, to help minimize errors and simplify changeovers.

- Consider adding barcode verification systems to help you verify your print quality and data validation.

- Run production tests to validate print quality, performance, and scalability before full deployment.

What is the best way to print 2D codes?

Choosing between preprinted and in-line printed 2D codes requires careful consideration of factors such as your traceability goals, production processes, and the needs of end users. Videojet specializes in in-line coding solutions and can guide you in selecting the approach that best suits your operations.

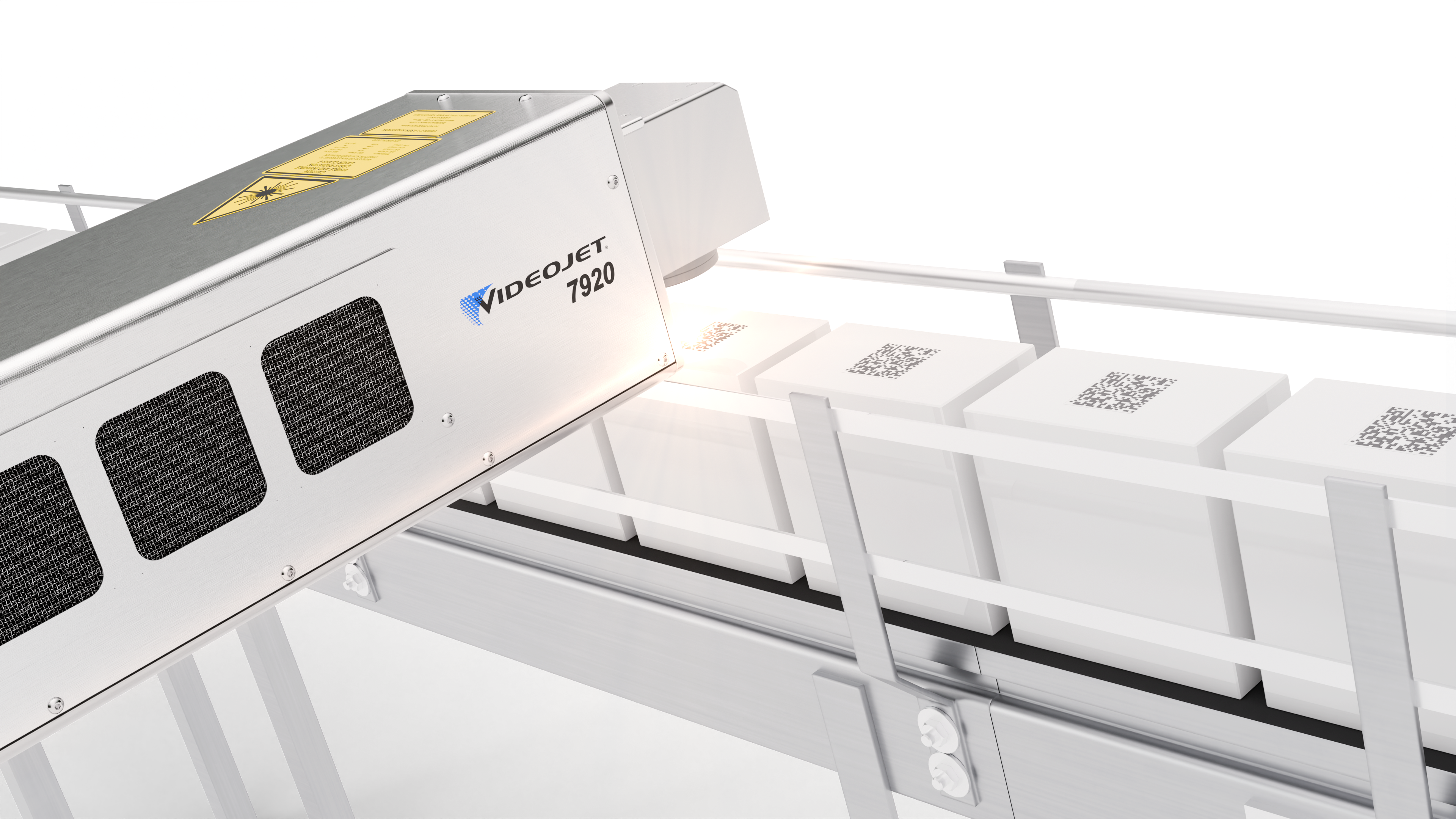

Videojet offers advanced in-line coding technologies designed for easy integration with your production lines, including:

- Thermal inkjet printers

- Laser marking systems

- Thermal transfer overprinters

- Continuous inkjet printers

- Code assurance software

Videojet also provides testing services to confirm compatibility with your packaging materials. Ready to optimize your 2D coding process? Discover how Videojet solutions can help you stay ahead.

Go deeper

Videojet article: GS1 2D codes: Pre-print or print in-line for Sunrise 2027?

Videojet article: Success with GS1 2D codes and Sunrise 2027 compliance

Videojet article: GS1 Sunrise 2027: The transition period

Videojet article: Essentials of printing barcodes and QR codes®

QR Code is a registered trademark of DENSO WAVE INCORPORATED.