Brent Vodraska, Videojet regional product manager

01 August 2025

Why traceability is crucial in electronics manufacturing

As electronics manufacturing evolves with smaller components and diverse product variations, traceability has become essential, especially in critical industries like aerospace, healthcare, defense, and power generation. Traceability tracks components throughout their lifecycle, helping to ensure safety, reliability, and alignment with standards such as UL, ISO, and MIL-STD Digital Product Passport (DPP).

Regulatory and industry standards require precise alphanumeric codes, barcodes, and compliance logos to support safety, environmental responsibility, and traceability. Technologies like 2D codes (e.g., QR and DataMatrix) serve as ‘digital passports,’ enabling lifecycle tracking and facilitating recycling efforts.

Top challenges of printing and marking on electronics

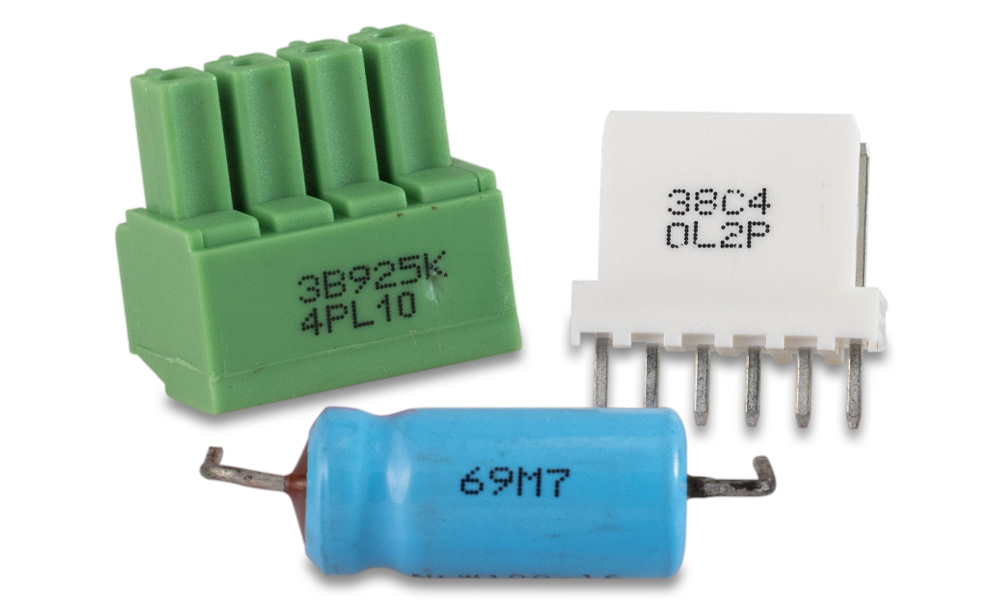

Marking electronics products, from components to finished parts, requires overcoming unique challenges related to material diversity, precision, and durability:

- Durability: Marks must withstand harsh environments, including high temperatures and chemicals.

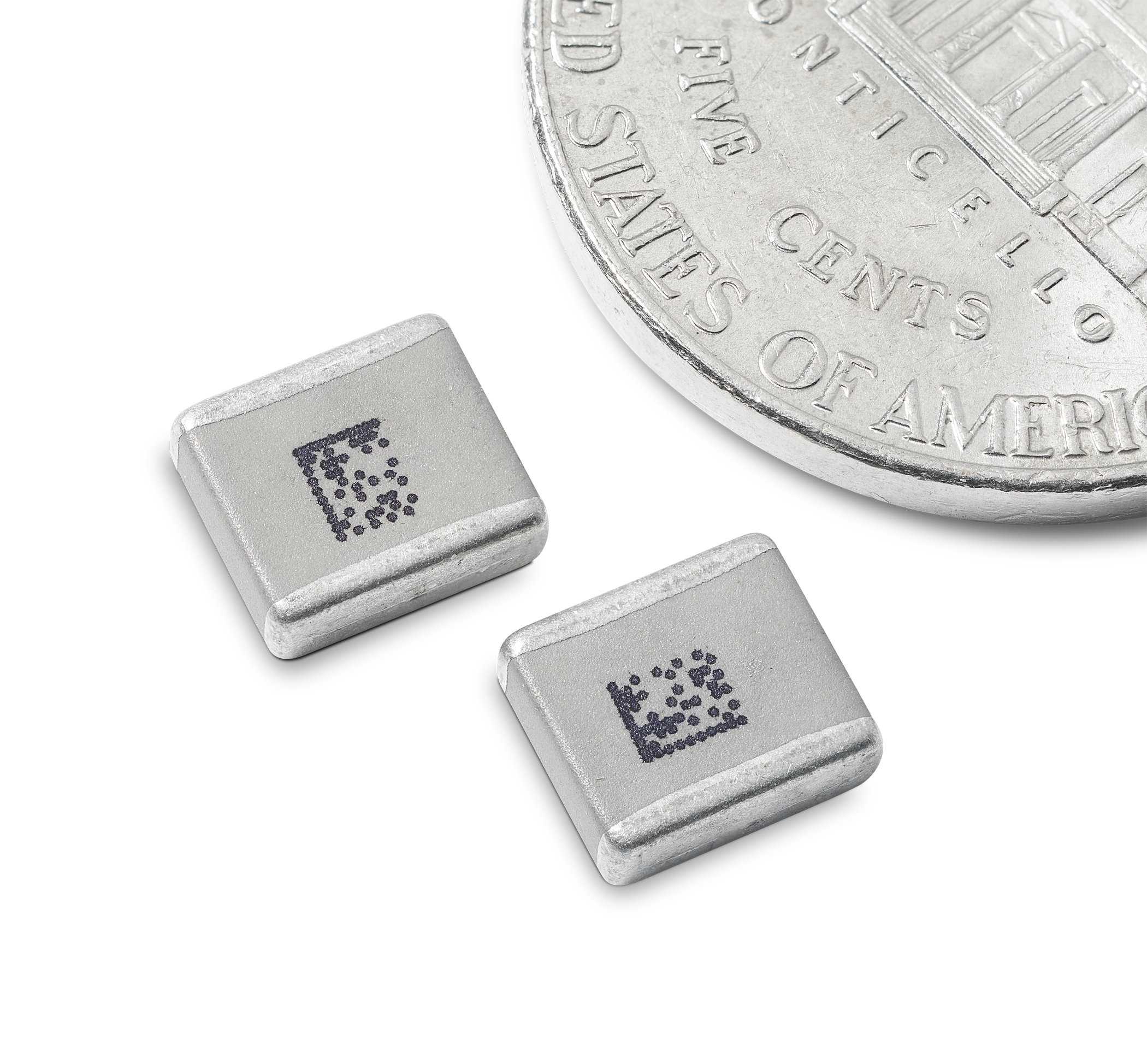

- High-resolution demands: Tiny components require micro-sized, legible marks.

- Material variety: Diverse materials, such as plastics, polyimides, and metals, can be difficult to mark due to properties like low surface energy.

- Thermal sensitivity: Heat-sensitive components, such as lithium-ion batteries, require non-damaging marking techniques.

- Cleanroom compatibility: Many electronics are produced in cleanrooms, restricting the use of certain marking technologies.

Parts, components, products – coding and marking solutions that meet the challenge

Product coding is critical for traceability, compliance, and brand protection throughout the product lifecycle. Two coding technologies, laser marking and continuous inkjet (CIJ) printing, are often chosen to meet the demands of electronics manufacturers.

CIJ vs. laser

The choice between CIJ printing and laser marking comes down to factors including how the printer or laser interacts with the surface to be marked; expectations for the code’s resolution and adhesion; and an operation’s line speed and integration requirements.

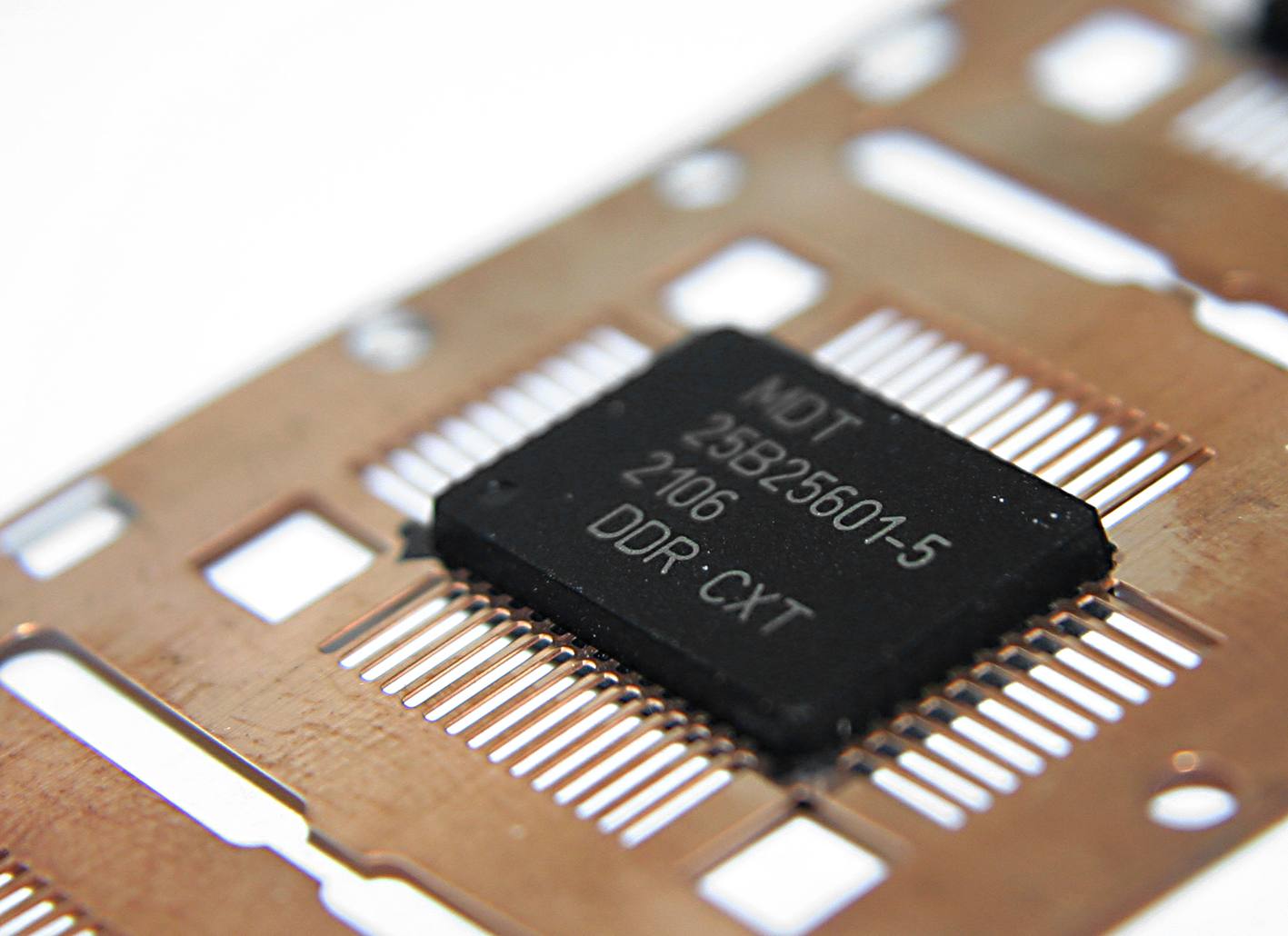

Coding printed circuit boards (PCBs)

- Laser marking: Fiber lasers create permanent 2D codes and other marks on metal PCBs, while CO₂ lasers work well for non-metallic surfaces.

- CIJ printing: High-speed, non-contact printing of alphanumeric text and 2D codes supports efficiency in fast-paced production lines.

Coding battery cells and modules

- Laser marking: Fiber lasers excel at marking metal casings, while UV lasers are ideal for heat-sensitive plastic housings and laminated pouches.

- CIJ printing: Offers precise marking of alphanumeric codes and 2D codes on battery casings, button cells, and plastic exteriors.

Coding chips and integrated circuits (ICs)

- Laser marking: Fiber lasers create durable marks on metal; CO2 lasers work well on plastic ICs; and UV lasers are ideal for delicate materials.

- CIJ printing: Capable of producing small, accurate codes on irregularly shaped ICs at high speed.

Coding metal parts, connectors, and components

- Laser marking: Fiber lasers deliver permanent, detailed marks on metallic components.

- CIJ printing: Flexible and capable of printing on metal surfaces with a variety of ink options to meet handling and adhesion requirements.

Coding cables and tubing

- Laser marking: UV lasers create sharp, durable marks on plastic tubing and cables while preserving material integrity.

- CIJ printing: Select CIJ solutions employ pigmented inks for excellent visibility and high-contrast codes on dark and colored surfaces.

Coding plastic electronic parts and components

- Laser marking: UV lasers provide crisp, high-contrast marks on heat-sensitive plastic shrink wrap, such as polypropylene, without thermal damage. Fiber lasers are ideal for marking on high-density plastic.

- CIJ printing: Provides versatile options for printing alphanumeric text, 2D codes, and logos on plastic surfaces, using specialized ink formulations designed for different types of plastic materials.

Printing and labeling outer packaging

- Print and apply labeling: Automates labeling with real-time customization, printing variable data like barcodes and shipping information directly onto labels, reducing label inventory, and improving efficiency for frequently changing product requirements.

- Large character marking (LCM): Enables high-speed, high-quality printing of text, logos, batch codes, and barcodes directly onto outer cases and pallets, supporting compliance and streamlining logistics in high-volume production environments.

How advanced marking technologies combat counterfeiting in electronics

Counterfeiting is a growing threat in the electronics industry, jeopardizing product reliability, regulatory compliance, and brand trust. Advanced marking technologies help combat counterfeiting by offering:

- Unique product identifiers: Both serialized and batch-specific codes make replication more difficult for counterfeiters.

- Algorithmic code generation: Smart coding software creates unique, traceable codes that are nearly impossible to replicate.

- Supply chain visibility: Secure, traceable codes help prevent product diversion and support product authenticity, protecting brand integrity and consumer confidence.

By implementing advanced coding and marking solutions, manufacturers can safeguard their products, reputation, and supply chains from counterfeit risks.

Electronics manufacturing moves fast—and so do we

At Videojet, we don’t just supply marking equipment. We build end-to-end solutions that help you boost efficiency, support compliance, and stay ahead of industry shifts

Here’s how we support you at every stage:

Operational efficiency

Videojet marking solutions streamline production processes by minimizing downtime and maximizing output. Available high-speed technologies enable rapid, reliable marking without compromising quality, all while keeping up with modern manufacturing demands.

Compliance and traceability

Meeting regulatory standards is critical for electronics manufacturers. Videojet systems provide accurate, consistent codes to help you comply with global regulations while enabling traceability across the entire supply chain.

“With highly detailed and visible CIJ printing and laser marking, Videojet helps electronics manufacturers meet the dual demands of operational efficiency and regulatory compliance.”

Brent Vodraska, Videojet product manager

Innovating for the future

With decades of experience in the electronics industry, Videojet is dedicated to addressing its unique challenges through continuous research and development.

Ongoing innovations are tailored to meet the evolving needs of electronics manufacturers, keeping you competitive in a rapidly changing market.

To discover how Videojet coding marking solutions can optimize your electronics manufacturing processes, visit Videojet Electronics Solutions.

Additional reading

Videojet: Electrical Components and Electronics

Videojet: Application note: Coding and marking of electronic components

Stay ahead with real-time updates on the latest news: