Also see:

Videojet® 7230/7330 Fiber Laser Markers

Laser Marking Systems ![]()

Powerful Fiber Laser Marking Machine for total operational freedom

The Videojet 7230 and 7330 Fiber Laser marking systems have been developed to meet the needs of manufacturers who work with robust, high-density materials, and are versatile fiber lasers that offer high-speed marking, with complex data, easy operability and industry-leading integration capabilities.

The 7230 and 7330 Fiber Laser marking systems offers you enhanced productivity benefits by allowing you to mark more products and codes, faster than previous Videojet lasers , due to a combination of improved data processing speeds and competitive marking speeds of up to 2,000 characters per second (speed based on 6mm marking head and substrate dependant). You can also benefit from a versatile laser solution that is available with the option of a 6mm and 10mm marking head, covering a wide variety of marking and coding operations.

Achieve easy integration and greater versatility in tight spaces with a combined laser head and controller weight of less than 25kg – 44% lighter than other fiber laser providers, allowing for simple integration into complex machinery.

Choose from a variety of user interfaces to control your Videojet 7230 and 7330 Fiber Laser marking system, allowing for simple operation and message creation, with a familiar look and feel touchscreen interface to help reduce user errors in production lines. Videojet Touch Control Software (TCS+) is designed to offer you flexible integration, simple operation and remote laser control through either the Videojet TU430 10.1” color touchscreen interface, or from virtually any browser-based device. Also available with the 7230 and 7330 Fiber Lasers, the advanced Videojet CLARiTY™ laser controller features an intuitive color touchscreen also used in other Videojet marking and coding solutions, that allows for simple operation and continuous improvement in uptime and productivity.

Contact us for New Equipment Sales: +65 3138 2040

Videojet 7230/7330

Specs

| 7230 | 7330 | |

| Laser Tube | Solid State Fiber | Solid State Fiber |

| Maximum Power | 10W | 20W |

| Laser Cooling | Fan | Fan |

| Maximum Line Speed | 900 m/min (2,940 ft/min) | 900 m/min (2,940 ft/min) |

| Environmental Protection | IP21, IP54 (laser head) | IP21, IP54 (laser head) |

| Beam Output | Steered Beam | Steered Beam |

| Laser Source Expected Life | >100,000 hours | >100,000 hours |

| Laser Wavelength Options | 1.055 – 1.075μm | 1.055 – 1.075μm |

| Focal Distance Options | 50 mm (1.96 in) – 420 mm (16.53 in) | 50 mm (1.96 in) – 420 mm (16.53 in) |

| Maximum Mark Window | 498.5 x 361.5 mm (19.62 x 14.23 in) | 498.5 x 361.5 mm (19.62 x 14.23 in) |

| Standard I/O Connectivity | Product Detect, Line Encoder, Fume Extraction | Product Detect, Line Encoder, Fume Extraction |

| Standard User Interface | Touch Panel (TU430) | Touch Panel (TU430) |

| Optional User Inteface | PC, CLARiTY™ Laser Controller, TCS+, Smart Graph Com | PC, CLARiTY™ Laser Controller, TCS+, Smart Graph Com |

| Plant Air Used | No | No |

| Certifications/Approvals | CE | CE |

Benefits

Uptime Advantage

- Maximize performance with long-life laser source expectancy up to 100,000 hours mean time before failure (MTBF)

- Air-cooled laser source that virtually eliminates maintenance intervals

- No wear parts help to minimize downtime

Simple Usability

- Focus more on production and less on user interaction and maintenance with an easy-to-use laser solution that is intuitive to the operator without the need for additional training

- Reduce the risk of rework and recalls with familiar look and feel user interfaces, offering simple operation and message creation

- Choose from a variety of user interfaces to control Videojet laser marking systems, including Videojet Touch Control Software (TCS+) and Videojet CLARiTY™ utilized in other Videojet marking and coding solutions

Built-in Productivity

- Improve marking productivity with a combination of the largest marking window in the industry and 2000 characters per second marking speeds*

- Benefit from standard and customizable communication protocols

- Achieve top speeds with serialization data and complex codes, thanks to faster data processing capabilities versus previous Videojet lasers

Easy Integration

- Benefit from greater versatility in tight spaces with a compact, lightweight marking head weighing only 4.4kg*

- Seamlessly integrate the 7230 or 7330 fiber laser into your production line with EtherNet / IP™ and PROFINET**

- Achieve greater flexibility in production line integration with a choice of working distances, and the orientation option of either a straight or 90 degree marking head

*With 6mm laser marking head

**Ethernet/IP is a trademark of ODVA. PROFINET is a registered trademark of Profibus & Profinet International (PI).

“You just turn the switch on and it just works, every time.”

Operator – Automotive fluid storage, carrying and delivery manufacturer (case study)

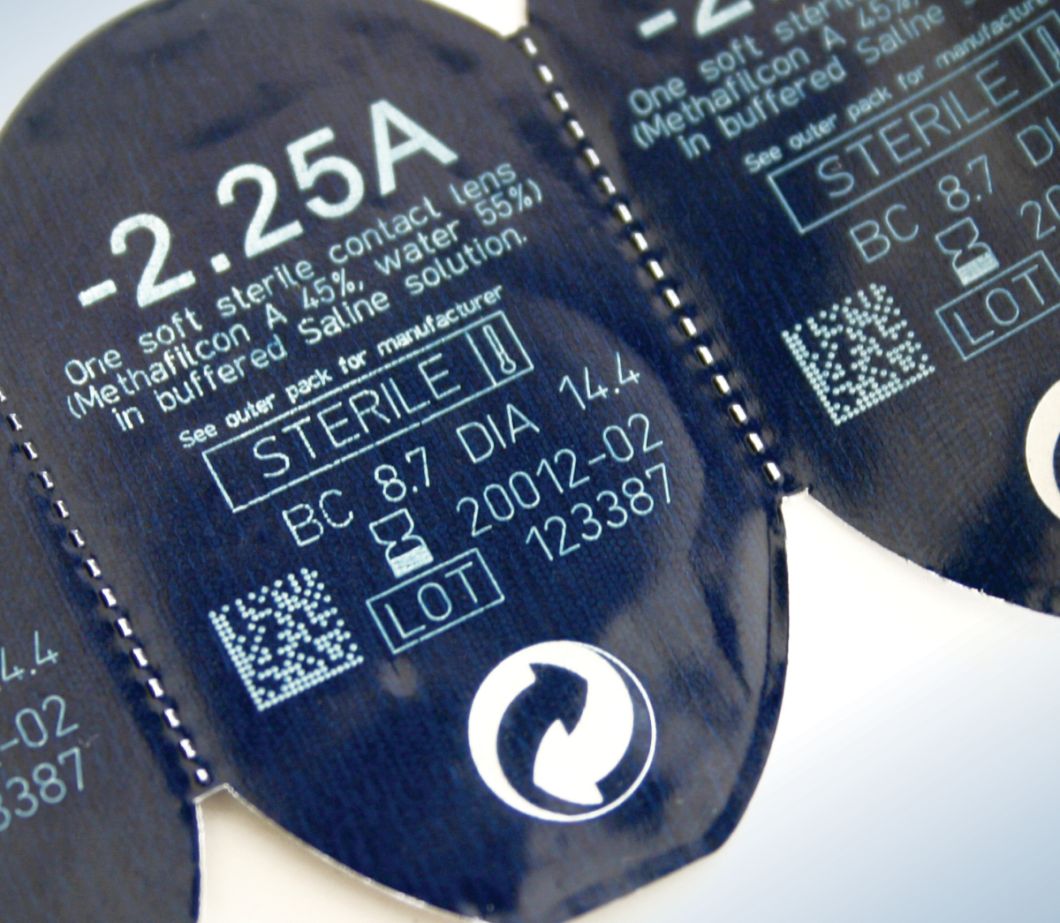

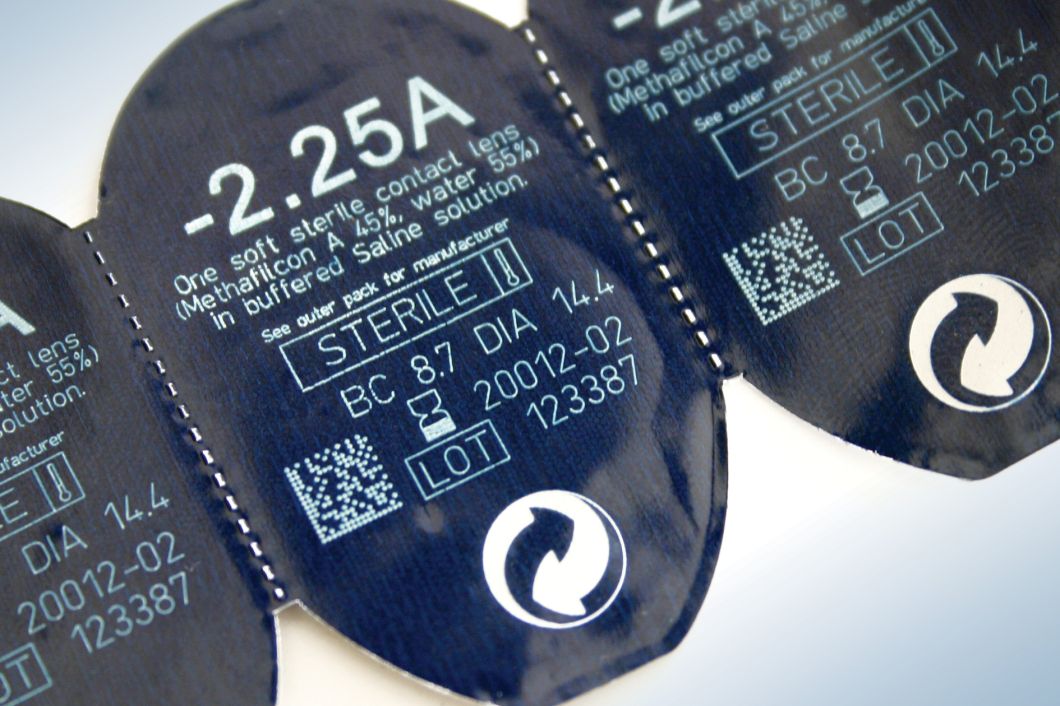

Applications

Related Products

Videojet 7230 Fiber Laser Marking Machine | Videojet 7330 Fiber Laser Marking Machine | Videojet 7340 Fiber Laser Marking Machine | Videojet 7440 Fiber Laser Marking Machine | |

| Description | The Videojet 7230 (10-Watt) and 7330 (20-Watt) fiber lasers are a light, compact and agile solution, designed to deliver high-quality, permanent codes for a wide range of marking applications. | The Videojet 7340 (20-Watt) and 7440 (30-Watt) fiber lasers are the first to feature the LightfootTM marking head, making them easy to integrate, operate and service. | ||

| Shared specs | – Most commonly used for marking metals and well suited for aluminum cans, cable and wire, polypropylene extrusions, bottles and other containers, blister pack, and aseptic packaging. Not recommended for transparent packaging as the light will pass through without marking. – Fan cooled | |||

| Max line speed | 900 m/min (2,940 ft/min) | |||

| Max power | 10-watt | 20-watt | 30-watt | |

| Wavelength options | 1.055 – 1.075μm | 1.04 – 1.09μm | ||

| Max mark window | 498.5 x 361.5 mm2 (19.62 x 14.23 in) | 126.3 x 64.46 mm2 (4.97 x 2.53 in) | ||

| Certifications/approvals | CE, TÜV/NRTL, FCC Compliance (no certification required): ROHS, CFRH/FDA | EtherNetIP DOC, ProfiNet/PNO certificate, CE, TÜV/NRTL, FCC Compliance (no certification required): ROHS, CFRH/FDA | ||

Contact Us

Let Us Find the Right Solution for Your Business

A Coding Expert will contact you within 1 business day

Contact us Today for Free Consultation & Demo Samples:

South East Asia, Australia & New Zealand:![]() : +65 3138 2040

: +65 3138 2040![]() : Marketing.Singapore@videojet.com

: Marketing.Singapore@videojet.com

Videojet Thailand![]() : +66 92 272 0132

: +66 92 272 0132

Videojet Vietnam![]() : +84 83 805 1033

: +84 83 805 1033

Videojet Presence in SEA/ANZ Countries